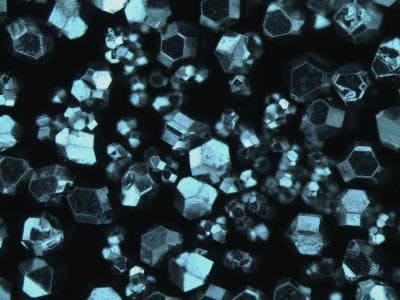

Diamonds are beautiful gemstones, which thanks to their shimmering sparkle and transparency look great in jewelry, but rough diamonds are much more interesting from a scientific point of view. The physical and chemical properties of diamond have made it a critical component for many devices in optics and electronics.

One of the promising areas of research towards diamond technological applications is diamond surface metallization, which is used to give the diamond surface new characteristics such as superior thermal conductivity, good thermal stability, improved wettability, and its original physical and chemical properties.

A group of scientists from Skoltech, the Lebedev Physical Institute of the Russian Academy of Sciences, and other leading scientific organizations have found a way to improve diamond adhesion—the bond between diamond and transition metal—using niobium. The study was published in the Journal of Alloys and Compounds.

"Diamond has two limitations related to the synthesis of large-sized diamond substrate and poor adhesion of metal contacts to the diamond surface. For example, when we worked on detectors for ionizing radiation and applied contacts made of gold and other materials, the adhesion of such contacts to diamond was very poor. At that point, we wondered how we could overcome such poor adhesion," explained Stanislav Evlashin, a co-author of the study and an assistant professor at Skoltech's Materials Center.

One of the most effective ways to metalize diamonds is by sintering it with such metals as titanium, chromium, tantalum, zirconium, and others. When they interact with carbon, a layer of metal carbide is formed. The authors of the study chose niobium because of its ability to form chemically stable films of niobium carbides on the diamond surface.

"We attempted to create a superconductor on the diamond surface and realized that if we deposit niobium on it and then anneal it, the following phase transformations occur during annealing: the niobium film after heating turns into the Nb₂C compound, and after further heating over 1200 degrees—into NbC," continues Stanislav Evlashin.

"Theoretical calculations of the constant lattice of niobium carbide depending on the concentration of carbon defects—often in the experiment there is a carbon deficiency—have shown that the used method of synthesis of niobium carbide on diamond allows to obtain high quality niobium carbide with a lattice parameter close to defect-free material," said Alexander Kvashnin, a co-author of the study and a professor at the Energy Transition Center.

"Calculations of the superconducting characteristics of niobium carbide showed a superconducting transition at a temperature of 19.4 K, which turned out to be close to the experimentally measured value. The results also indicate the high quality of the experimentally obtained film."

"Notably, the low concentration of defects in the obtained niobium carbide film leads to sufficiently high values of electron diffusion, compared to other niobium-based alloys. And this, together with the observed superconducting characteristics, is of practical interest for quantum detection devices," added Anna Kolbatova, a co-author of the study and a research scientist at Moscow Pedagogical State University.

The researchers proved that the obtained niobium carbide layer has superconductive characteristics. If this film is applied to the surface of diamond, it will be possible to create super-sensitive detectors due to its high thermal conductivity. The high thermal conductivity of diamond will help detect signals—it would happen much faster than with other materials.

The study involved two projects. The first project, "Investigation of the effect of alloying elements on the electrochemical characteristics of nanostructured carbon materials for the creation of promising current sources," aims to obtain results that can be used to create electrochemical sources of a new generation. The second project, "A new generation of quantum detectors and single photon sources based on two-dimensional Van der Waals structures," seeks to develop devices for quantum detection, that should surpass the traditional ones.

Among those also contributing to the study are Julia Bondareva, Fedor Fedorov, Alexander Egorov, and Nikita Matsokin.

More information: R.A. Khmelnitsky et al, Synthesis and characterization of niobium carbide thin films on diamond surface for superconductive application, Journal of Alloys and Compounds (2023). DOI: 10.1016/j.jallcom.2023.173266.